Email us at: sales@shibochina.com

Email us at: sales@shibochina.com

small, medium and large models are in stock available

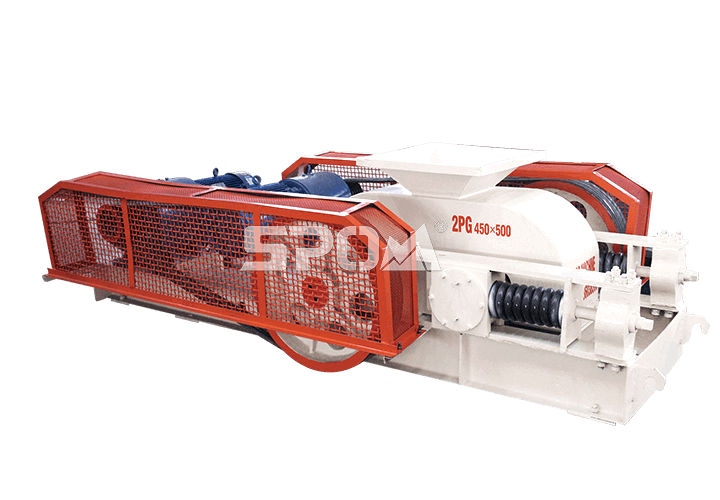

Feeding Size: ≤130mm Processing Capacity: 10-125t/h

Hot model2PG450×500 2PG700×400 2PG600×800

Output sizedifferent sizes for 120 kinds of stones

20-30mm

10-20mm

5-10mm

0-5mm

PG Double roller crusher is mainly used to crush material which is below the medium hardness, such as clinker mineral, coke, slag, shale, limestone and so on. It is the most suitable for small and medium non-metal mines and chemical industries to undergo secondary and fine crushing. It has the following features: simple structure, reliable performance, less flour.

1. Adaptable and flexible application

2. the use of wear-resistant materials,more durable

3. High production and high crushing efficiency

4. Equipped with dustproof and silencing device, zero dust and zero noise.

The adjustment of discharging granularity: There is a wedge-shaped or gasket adjustment device between the two rolls, and on the top of the wedge-shaped device, there is an adjusting bolt. When the adjusting bolt pulls up the wedge, the wedge will lift the movable roll from the fixed roll, so that the gap between the two rolls will become large, and the discharging granularity will become large. When the wedge goes down, under effect of the pressure spring, the gap between the two rolls will become small, and the discharging granularity will become small. The gasket device adjusts the discharging granularity through increasing and decreasing the number or thickness of the gasket, and when the number of the gasket increases, the gap between the two rolls will become large and the discharging granularity will become large; when the number of the gasket decreases, the gap between the two rolls will become large and the discharging granularity will become small.

| Model | Roller Diameter(mm) | Feeding Size(mm) | Discharging Size(mm) | Capacity(t/h) | Power(kw) |

| 2PG400x250 | φ400 | <25 | ≤3 | 5-10 | 5.5x2 |

| 2PG450x500 | φ450 | <30 | ≤3 | 8-20 | 7.5x2 |

| 2PG610x400 | φ610 | <30 | ≤3 | 13-35 | 15x2 |

| 2PG610x750 | φ610 | <30 | ≤3 | 16-40 | 22x2 |

| 2PG750x500 | φ750 | <30 | ≤3 | 16-40 | 22x2 |

| 2PG800x600 | φ800 | <30 | ≤3 | 20-40 | 30x2 |

| 2PG800x800 | φ800 | <30 | ≤5 | 20-50 | 37x2 |

| 2PGY1000x800 | φ1000 | <30 | ≤5 | 40-70 | 55x2 |

| 2PGY1200x1000 | φ1200 | <30 | ≤5 | 60-100 | 90x2 |

| 2PGY1200x1200 | φ1200 | <30 | ≤5 | 80-130 | 110x2 |

| 2PGY1500x1000 | φ1500 | <30 | ≤5 | 100-150 | 132x2 |

| 2PGY1500x1200 | φ1500 | <30 | ≤5 | 150-200 | 160x2 |

| 2PGY1800x1000 | φ1800 | <30 | ≤5 | 220-300 | 200x2 |

| 2PGY2000x1200 | φ2000 | <30 | ≤5 | 300-400 | 250x2 |

| The above data are for reference only and are subject to specific conditions. | |||||

Copyright © 2012-2020 Zhengzhou Shibo Machinery Manufacturing Co., Ltd. All Rights Reserved.