Capacity: 20-1000TPH

Feeding size:: Max. 500mm

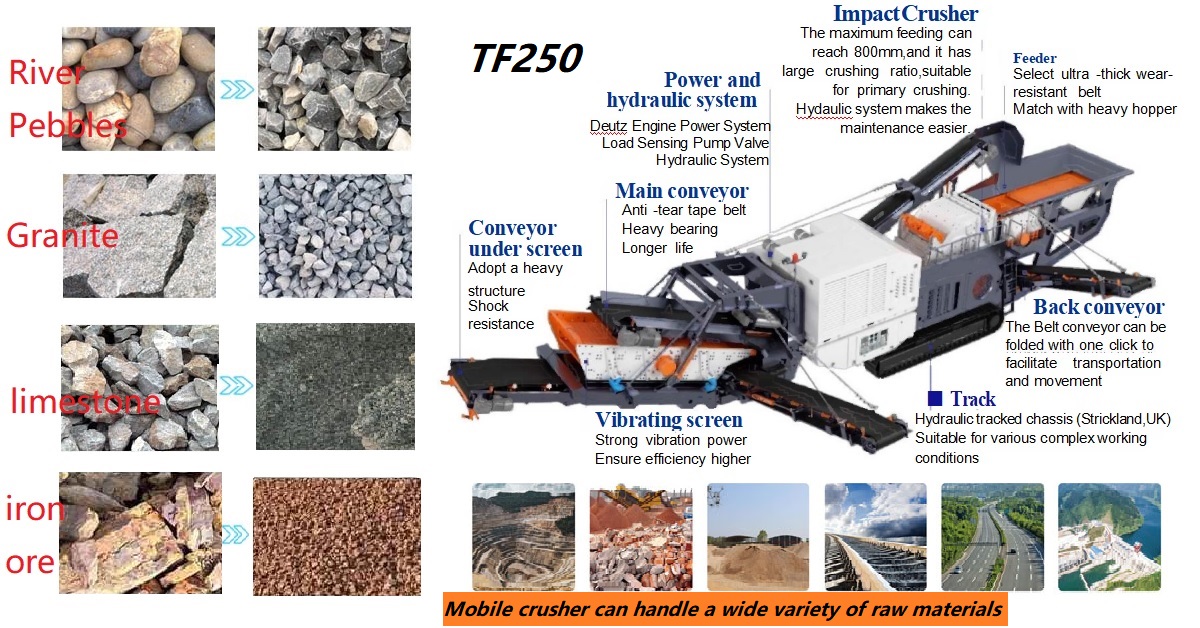

Processed Materials: Granite, Basalt, Limestone, River stone; Feldspar; Andesite, Phonolite, Dolomite, Barite, Construction Waste; Iron Ore, Copper Ore, Zinc Ore, Manganese Ore; iron tailings, etc.

Application: Infrastructure construction, mining, garbage treatment, stone processing, railways, highways, water conservancy projects,etc.

Email: sales@shibochina.com

Email: sales@shibochina.com

Mobile crushers reduce hauling costs and increase productivity

Mobile crushers are often referred to as ‘mobile crushing plants’. They are track-mounted crushing machines which, thanks to their mobility, can maximise productivity and reduce operating costs – while increasing safety and reducing environmental impact.Tracked mobile crushers meet the same basic criteria as stationary plants, crushing as well as mobility properties improved notably. The ability to crush also the largest lumps to the desired cubicity at the desired rate, the basic components of mobile crushers are almost the same as for stationary ones, but with the added advantage of complete mobility – even up slopes as steep as 1:10 incline.

Mobile cone crushers

Mobile cone crushers are traditionally used as secondary, tertiary, and quaternary crushers. However, if the grain size of the processed material is small enough by nature, then they can also operate at the first stage of the crushing process. The tracked cone crusher for maximizing production;they are renowned for achieving significant rates of reduction,cubical product shape and providing high quality aggregate and sub-base material. Also, befitted with a recirculating conveyor and single deck screen to further reduce oversize materialin a complete pass. In the application of mobile crushing station, it is equipped with high performance and high-capacity CS cone crusher and HP Serious Hydraulic Cone Crusher in two-stage and three-stage fine crushing.Mobile cone crusher can achieve high productivity,large crushing ratio and excellent grain shape.

Mobile impact crushers

Mobile impact crushers are wide-ranging crushing machines that fall into two distinctive categories according to the crushing technology they use. Mobile HSI crushers have a horizontal impact crushing unit and they are used as primary, secondary, or tertiary crushers. Mobile VSI crushers, in turn, are equipped with vertical shaft impact crushing unit, and they are extremely efficient in the last stage of the crushing process, producing precisely shaped cubical end products. our tracked impact crushers are designed forprimary,secondary crushing of construction materials in demolition/recycling/quarry &mining applications and feature thick heavy duty blow bars for longer life and utllization.It provides a consistent reduction in size and excellent product shape,powered by direct driven system,which is efficient and easy to operate,with reliability and optimum maneuverability.

Mobile jaw crushers

Popular mobile jaw crushers are generally utilized as primary crushers that reduce the material to smaller sized for further processing. Our mobile jaw crusher can be quickly put to workand moved from one location to another which is available in a range of sizes.Design of trackedjaw crusher perfected over many years gives impressive outputs when crushing even the hardest of materials..

Mobile VSI Sand Making Machine

Mobile VSI Sand Making Machine, the track mounted sand making and screening plant can caterfor both shaping and sand making modes of operation.It can be combined with other crawler mobile stations or operated independently.It is an important component in the production of high-quality aggregates.

Mobile Screens

Mobile Screens, Mobile Screeners, Mobile screening equipments are a cost-effective and flexible way to screen material at your production site. Our wide range of mobile screening equipment provide excellent productivity in smaller aggregates production sites, larger quarries and in mining applications.The tracked screen unit utilize high efficiency inclined vibrating screen boxes.Robust tracks ensure excellent on site positioning and mobility together with operational stability.Variable speed forward and side product conveyors are hydraulically operated and easily stowed for transport.

Strict quality control system and decades of years production technology make stone crusher plant better performance, higher crushing efficiency and longer service life.

Full and complete service system, professional team, guarantee the production efficiency

Specific solutions for you to meet small, medium and large sized production needs

Product installation,commissioning, technical training, etc

Copyright © 2012-2020 Zhengzhou Shibo Machinery Manufacturing Co., Ltd. All Rights Reserved.