-

Feeding Size 50-940mm

Feeding Size 50-940mm -

Processing Capacity 90-650t/h

Processing Capacity 90-650t/h

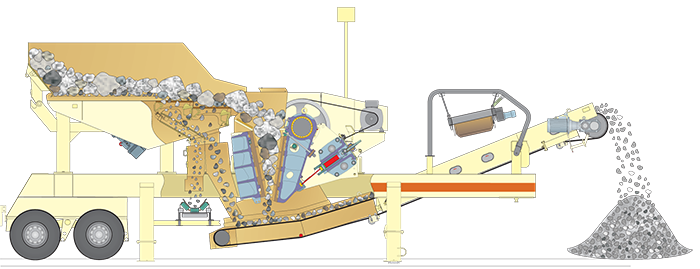

Tire-type mobile crushing plant is a new type of mobile crushing equipment, which can supply the customers the best crushing and screening solutions. Considering from the customers’ standpoint, efficiently integrates the feeding equipment, crushing equipment, screening equipment, effectively solving the site constraints of the fixed crushing plants. It not only avoids the site infrastructure, but also expands the material stack space due to the compact equipment layout. Mobile crushing plant has the obvious advantages of crushing while moving, winning more and more customers’ recognition, Mobile crushing plant is divided into mobile jaw crusher plant, mobile impact crusher plant, mobile cone crusher plant, which is widely used in the road and bridge construction, urban construction, metallurgy, energy, and other crushing and screening industries.

20-30mm、10-20mm、5-10mm、0-5mm

It can crush more than 100 kinds of rocks. The common discharge size is...

Stable performance

Stable performance Moving flexible and High efficiency

Moving flexible and High efficiency Shorter transportion time and lower installation cost

Shorter transportion time and lower installation cost Quickly access to the operating mode

Quickly access to the operating modeWhen working, the materials are evenly transported into the crusher by the feeder. After the crusher performs preliminary crushing, a closed-circuit system is formed by the circular vibrating screen to realize the cyclic crushing of the materials, and the finished materials are output by the conveyor for continuous crushing operation. The mobile jaw crusher can remove the circular vibrating screen according to the actual production needs, and actually firstly crush the material directly, and it is flexible and convenient to use in conjunction with other crushing equipment.

| The Standard Model | Corollary Equipment | Corollary Equipment | Transport Dimension(mm) | ||

| Model | Feeding Size(mm) | Capacity(t/h) | |||

| S-CS75 | 3YZK1848 | CS75 | ≤160 | 59-163 | 12600×2800×4400 |

| S-CS110 | 3YZK1860 | CS110 | ≤178 | 100-200 | 13800×3000×4400 |

| S-CS160 | 3YZK2160 | CS160 | ≤188 | 132-253 | 13800×3000×4400 |

| S-CS220 | 3YZK2160 | CS220 | ≤230 | 215-330 | 14500×3000×4500 |

| S-Q300 | 3YZK1848 | SQ300 | ≤160 | 105-205 | 12600×2800×4400 |

| S-Q400 | 3YZK1860 | SQ400 | ≤230 | 235-575 | 13800×3000×4400 |

| S-Q500 | 3YZK2160 | SQ500 | ≤240 | 304-640 | 14500x3000x4600 |

| S-H420 | 3YZK1848 | SH420 | ≤240 | 85-170 | 12600×2900×4400 |

| S-H430 | 3YZK1860 | SH430 | ≤360 | 120-345 | 13800×3000×4500 |

| S-H440 | 3YZK2160 | SH450 | ≤450 | 255-605 | 14800×3200×4600 |

| S-HP100 | 3YZK1860 | SHP100 | ≤140 | 75-140 | 13800×2900×4300 |

| S-HP200 | 3YZK2160 | SHP200 | ≤185 | 145-250 | 14200×3000×4500 |

| S-HP300 | 3YZK2160 | SHP300 | ≤230 | 220-440 | 16500×3200×4600 |

| S-PF1214 | 3YZK1860 | PF1214 | ≤300 | 100-200 | 14500×2900×4500 |

| S-PF1315 | 3YZK2160 | PF1315 | ≤350 | 130-280 | 15200×3000×4500 |

| S-PF1320 | 3YZK2460 | PF1320 | ≤500 | 180-400 | 15200×3000×4500 |

| S-S1860 | 3YZK1860 | ≤400 | 65-586 | 10500×2700×4200 | |

| S-S2160 | 3YZK2160 | ≤400 | 81-720 | 10500×3000×4500 | |

| S-S2460 | 3YZK2460 | ≤400 | 100-810 | 10500×3200×4500 | |